Prefabricated Houses Manufacturers

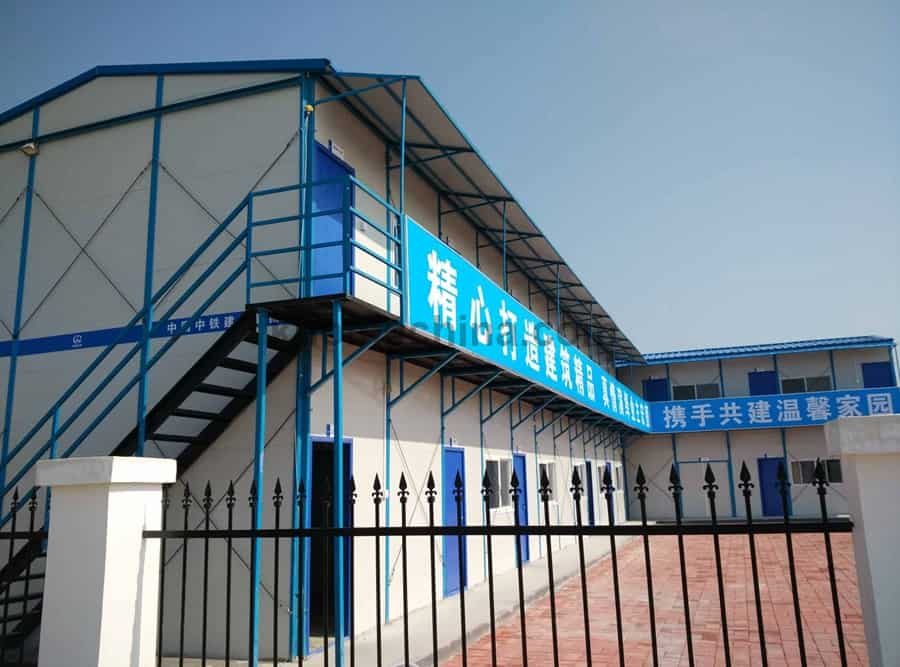

China Prefabricated houses use light steel as the skeleton, sandwich panel as the enclosure material, and uses standard modulus series for spatial integration, and then the components are connected by bolts to build an environmentally-friendly and economical prefab modular buildings. It can be assembled and disassembled conveniently and quickly, realizes the general standardization of temporary buildings, and establishes an environmentally friendly, energy-saving, fast, and efficient construction concept, and makes the temporary housing enter a series of development, integrated production, supporting supply, inventory, and availability. The field of stereotyped products is used for many times of turnover.

Modular Prefab Houses

K-home is one of the best suppliers of panelized prefabricated houses and prefab homes that have become a potent requirement in the construction fields.

We have all kinds of prefab homes and similar solutions like prefabricated dormitory, temporary buildings schools, portable classroom buildings, container commercial buildings, affordable prefab homes, prefab camps, prefab worker camps, prefab offices, prefabricated porta cabins, flat-pack site cabins, prefabricated construction, pre-assembled buildings, field hospital container, ablution container, modular medical center, portable school buildings and other kinds of homes.

Prefabricated Houses Features

- The mainframe is made of light special cold-rolled C steel, and bolts are used between the parts connect, achieve activity and relocation;

- The exterior wall panels are made of steel sandwich panels (the color panels are imported on-line paint, the life is more than ten years, the middle is flame-retardant polystyrene, which is formed by the adhesive, beautiful and durable) directly inserted into the column slot during installation, No other fixed connection is required) to achieve mobility, no loss during the second disassembly and assembly.

- The partition wallboard adopts double-sided color steel sandwich board or magnesium-phosphorus fireproof board, which is connected by a fixed card code during installation, and there is no loss during the second disassembly and assembly.

- The roof adopts color-steel profiled PU tile foam insulation tiles, which are connected with the roofing sandalwood strips with self-tapping nails during installation, and each tile overlaps with a profiled bag to effectively ensure that the roof does not leak. It is only necessary to pull out the self-tapping nails, and the roof tiles are not damaged.

- All windows are made of stereotyped standard board room materials, all of which are light and new materials.

Product Details

Benefits of Prefabricated Houses

Frequently Asked Questions

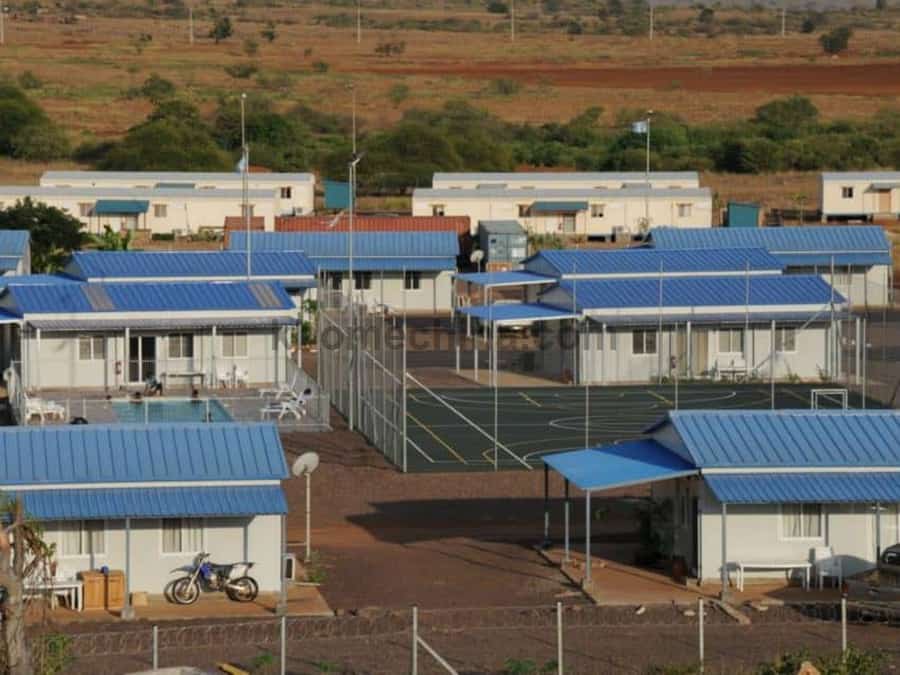

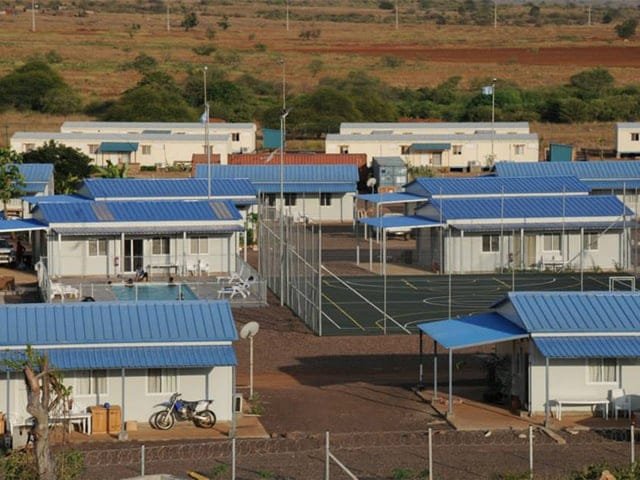

Related Projects

Related Articles

SEND A MESSAGE